HSE Requirement Procedures

The purpose of these procedures is to clarify HSE requirements for administration and operations, and to give guidance and instruction as to how this requirement can be met. BMP Director has the ultimate responsibility for HSE within the organization. The Director has delegated this responsibility to Operations Manager and Line Managers, who are responsible for implementing and complying with all aspects of these procedures.

All employees have a constant duty to ensure the HSE and welfare of themselves, as well as their colleagues, and he has duty of complying with these procedures at all time

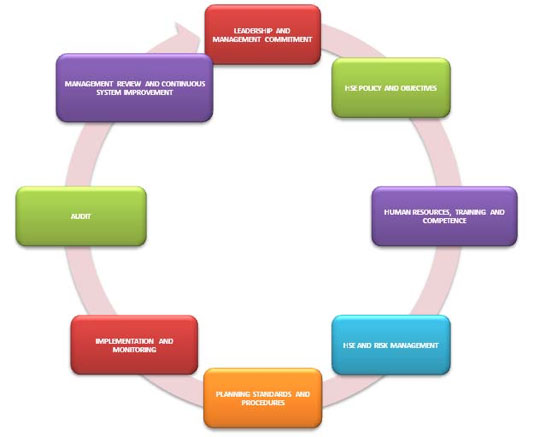

Continuous Performance Improvement

Continuous improvement of the BMP HSE Management System Operating Company is achieved by following the flow chart as shown in the figure below.

Communication

BMP will maintain effective communication networks to allow the HSE management system to function to its full potential. This will include but shall not be limited to the use of the BMP intranet, safety booklets, HSE meetings, safety alerts and safety campaigns. In addition HSE will be a key topic on all meeting agendas.

Accident/Incident/Issue Reporting

Incident reporting can be divided into 3 priority number as follows:

- Initial verbal report (1 hour reported).

- Initial accident/incident report (max. 24 hours reported), divided into 2 forms reporting such as Investigation and Employee Statement Form and Preliminary Notification Form.

- Accident/incident investigation and report (3 man team) using Accident/Incident/Issue Investigation and Reporting (max. 96 hours reported) or 1 week if required (usually required if medical treatment (or greater) or damage or loss in excess of USD 10,000.00).

Occupational HSE Orientation and Training Program

BMP has developed an occupational HSE orientation and training program which is a series of hands-on experiential classroom training sessions. This program is designed to familiarize each employee not only with the physical rig and equipment, but also the culture and values organization. The aim of these workshops is to further enhance BMP’s culture by developing leadership skills while defining our core values.

Management Review

The BMP HSE Management System is periodically reviewed by Senior Management. The review is conducted with all executives present including the Director and General Manager. This high level of involvement is indicative of the culture of BMP that values HSE management.